Workmanship

For its products, Artigiangomma uses selected materials of the highest quality to guarantee the strength and solidity over time, right from the internal structure. We complete the various processes in-house to achieve the finished product – including rubber cutting, feathering and padding.

For example, Artigiangomma’s feather cushions are made of sterilised goose down that has not been regenerated, being either pure or at a 30% blend with hollow silicone polyester ball fibre.

In addition, the cushion cover is made of 100% cotton with a titration of 20/30, offering extensive feather-holding capacity.

In addition to the padding of its frames, Artigiangomma uses a range of processing methods.

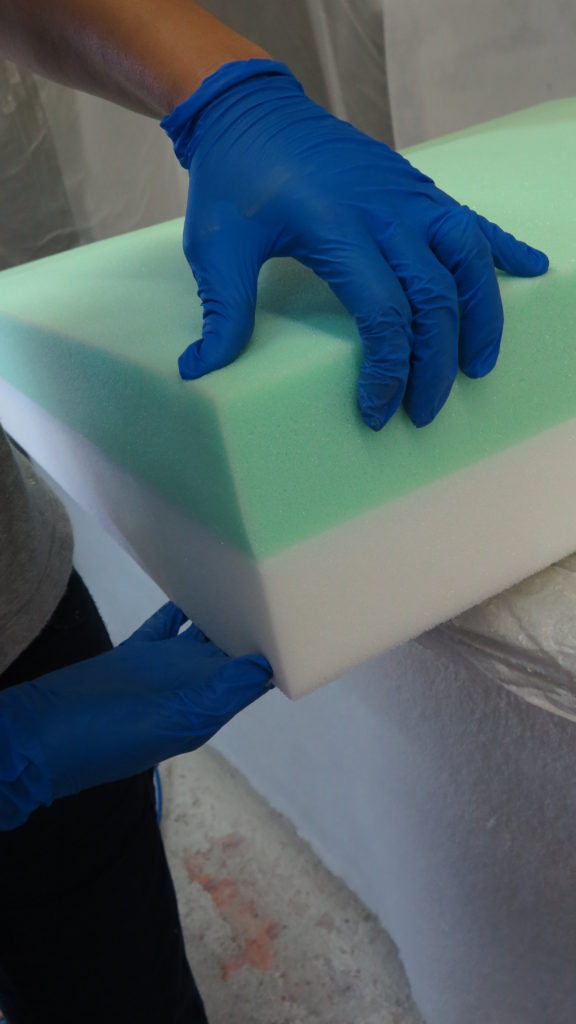

The most common include padding the frame with polyurethane which is subsequently covered with a layer of wadding or velveteen coupled with various thicknesses of polyurethane.

Alternatively, it is possible to create a cover entirely made of goose down.

Custom made in Tuscany

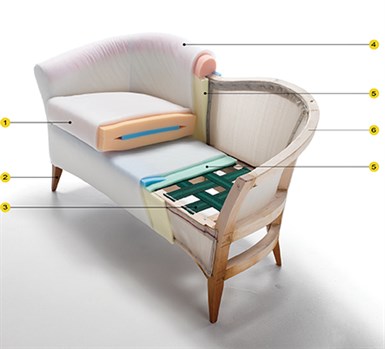

- Seat Cushion: high-density polyurethane and wadding

- Painted solid wood feet

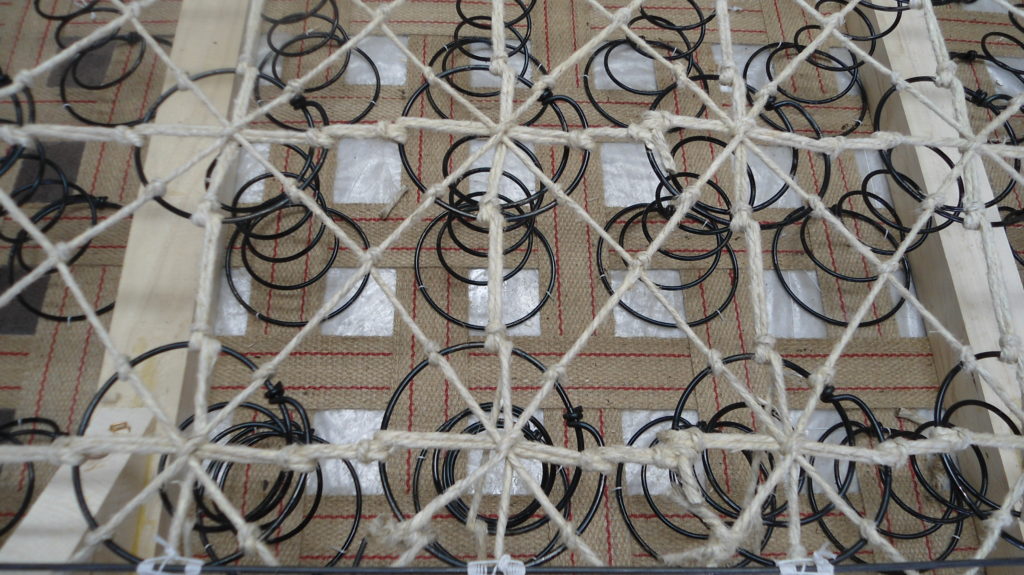

- Elastic straps

- Wadding: polyester fibre coupled with velveteen to cover rubberised frames

- Medium-density polyurethane for the frame padding

- Solid wood frame

Rubber-cutting

Foam rubber (polyurethane) is a soft and spongy material that is mainly used to cover chairs and sofas, for upholstery and cushions.

Feathers

Being soft and warm, feathers are the perfect padding for beds and sofas, especially for stuffing cushions.

Tufted padding

Tufting is a type of upholstery for sofas, armchairs or headboards developed around 1800. This padding is entirely handmade and quilted to form padding arranged in a square or rectangular form. The quilted fabric is then held with buttons or studs.